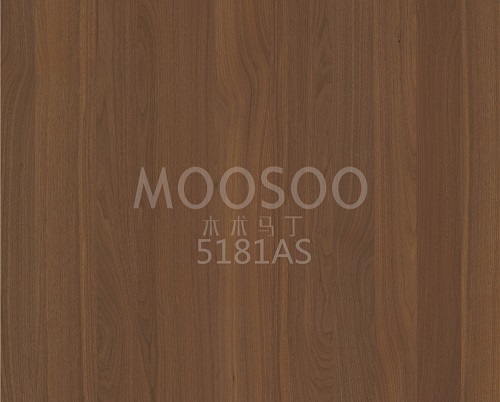

In modern woodworking and interior design, materials that combine natural aesthetics with durability are increasingly in demand. Among these, the White Elm Steel Brushed Solid Wood Splicing Board stands out as a premium option. This engineered wood product integrates the inherent beauty of white elm with advanced finishing and structural techniques, producing a surface that is both visually striking and mechanically reliable.

Material Composition and Characteristics

1. White Elm (Ulmus americana and related species)

- Grain and Color: White elm is known for its interlocking grain patterns, moderate texture, and pale to medium brown tones, often accented by darker streaks.

- Density and Hardness: White elm typically has a density of 560–640 kg/m³ and a Janka hardness of 850–950 lbf, offering a good balance of strength and workability.

- Moisture Behavior: Elm has moderate dimensional stability; when kiln-dried and spliced properly, it resists excessive warping and cracking.

2. Steel Brushed Finish

The steel brushing process uses rotating steel bristle brushes to remove the softer springwood between growth rings, leaving a textured surface.

Advantages:

- Enhances the natural grain depth.

- Increases tactile character.

- Provides better adhesion for oils, stains, or sealants.

- Durability: The textured finish reduces the appearance of scratches and surface wear compared to flat-polished surfaces.

3. Solid Wood Splicing (Finger-Joint or Edge-Gluing)

- Definition: Splicing involves joining multiple solid wood segments to create large, stable panels.

Techniques Used:

- Finger-jointing: Interlocking cuts at the ends of wood strips bonded with industrial-grade adhesives.

- Edge-gluing: Long edges of wood boards bonded under pressure for seamless panels.

Benefits:

- Increases dimensional stability.

- Minimizes warping and internal stresses.

- Enables sustainable use of timber by reducing waste.

Technical Specifications

| Property |

Specification Range |

| Density |

560–640 kg/m³ |

| Janka Hardness |

850–950 lbf |

| Thickness (standard panels) |

15–40 mm |

| Width (customizable) |

200–1200 mm |

| Length (customizable) |

Up to 4000 mm |

| Surface Finish |

Steel brushed, sanded, or lacquer-ready |

| Adhesive Type |

E0/E1 grade formaldehyde-free glue |

| Moisture Content |

8–12% after kiln drying |

| Surface Treatment Options |

Oil, UV coating, varnish, polyurethane |

Manufacturing Process

- Log Selection: High-quality white elm logs are selected and cut into planks.

- Kiln Drying: Lumber is dried to achieve 8–12% moisture content, preventing future distortion.

- Splicing: Planks are trimmed, finger-jointed, and glued under controlled pressure.

- Surface Treatment: The steel brushing process enhances texture and prepares the surface for finishes.

- Calibration & Sanding: Panels are leveled to precise thicknesses.

- Finishing (Optional): Oil, lacquer, or UV coatings may be applied for protection.

Applications

- Furniture Manufacturing: Tabletops, cabinets, shelving, and benches.

- Interior Design: Wall cladding, ceiling panels, and flooring underlayment.

- Architectural Joinery: Stair treads, door panels, and window frames.

- Commercial Spaces: Countertops, reception desks, and retail displays where durability meets aesthetics.

Technical Advantages

- Strength and Stability: Spliced structure reduces the risk of cracking and bowing.

- Eco-Friendliness: Optimizes timber use by utilizing smaller sections of wood.

- Customizability: Wide range of dimensions, finishes, and coatings available.

- Enhanced Durability: Steel brushed surface minimizes visible wear and improves grip.

- Health and Safety: Adhesives meet E0/E1 formaldehyde emission standards, ensuring low VOC emissions for indoor use.

Limitations and Considerations

- Surface Roughness: Brushed surfaces may accumulate dust more easily and require proper cleaning.

- Moisture Sensitivity: Although splicing improves stability, prolonged exposure to high humidity can still cause swelling.

- Cost: Higher than standard plywood or particle board due to natural wood content and finishing processes.

Maintenance Guidelines

- Cleaning: Use a soft, damp cloth; avoid harsh chemicals.

- Humidity Control: Keep indoor relative humidity between 40–60% to prevent expansion or contraction.

- Protective Coating: Reapply oil or wax finishes every 12–18 months for optimal longevity.

- Repairs: Minor scratches can be sanded and refinished due to the solid wood composition.

The White Elm Steel Brushed Solid Wood Splicing Board is a sophisticated material that merges the natural appeal of elm with modern engineering techniques. Its structural stability, aesthetic character, and versatility make it suitable for both residential and commercial applications. While it requires careful maintenance and investment, its long-term durability and timeless appearance make it a valuable choice for premium woodworking and architectural projects.