The White Elm furniture splicing board represents the intersection of craftsmanship, material science, and modern interior design. As the demand for sustainable, durable, and visually appealing wood products increases, White Elm (Ulmus americana) has re-emerged as a sought-after species, offering remarkable grain patterns, mechanical stability, and workability for furniture and architectural applications.

Material Characteristics of White Elm

White Elm is a hardwood species native to North America, prized for its interlocking grain, moderate density, and resilience against splitting. Its Janka hardness rating averages around 830 lbf (3,690 N) — softer than oak but harder than pine — making it ideal for furniture that requires both strength and ease of machining.

Key properties include:

- Density: 560–700 kg/m³ (depending on moisture content and growth region)

- Modulus of Rupture (MOR): 97 MPa (excellent bending strength)

- Elastic Modulus (MOE): 11 GPa (providing good flexibility and impact resistance)

- Shrinkage (radial/tangential): 4.5% / 8.8% (moderate dimensional change)

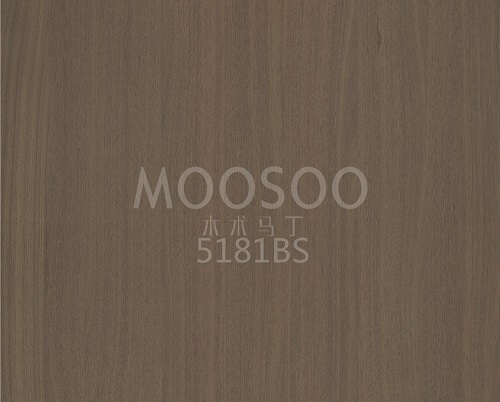

Its interlocked grain structure gives White Elm a distinctive ribbon-like figure when quarter-sawn, producing a visual texture similar to ash or chestnut. The pale, slightly reddish-brown hue allows versatile staining and finishing options.

The Splicing Board: Definition and Manufacturing Process

A splicing board, also known as a jointed or laminated board, consists of multiple narrow planks bonded edge-to-edge to create larger panels. This process maximizes yield from raw timber, minimizes warping, and allows for large-format furniture surfaces such as tabletops, cabinet fronts, and shelving.

The production process involves several technical stages:

- Moisture Conditioning: White Elm is kiln-dried to a stable 6–8% moisture content to reduce internal stress and ensure long-term dimensional stability. Elm’s interlocked grain requires gradual drying schedules to prevent honeycombing or surface checking.

- Finger-Jointing or Edge-Jointing: Individual strips are trimmed, planed, and finger-jointed or straight-edge glued. Finger joints increase the effective bonding surface area and improve mechanical strength, particularly for long panels.

- Adhesive Selection: High-performance adhesives such as polyvinyl acetate (PVA D4), melamine-urea-formaldehyde (MUF), or epoxy resins are used. The choice depends on the intended application — indoor furniture typically uses PVA, while kitchen or humid environments favor MUF for moisture resistance.

- Pressing and Curing: Hydraulic or cold pressing applies 0.6–1.0 MPa of pressure for 20–60 minutes, followed by curing at controlled temperature and humidity to achieve optimal bond strength.

- Surface Finishing: After sanding, the boards can be finished with oil, lacquer, or UV-curable coatings. White Elm’s open grain structure allows for a deep, tactile finish when treated with penetrating oils.

Mechanical and Dimensional Performance

- Bond Strength: Properly bonded White Elm splicing boards exhibit tensile and shear strengths exceeding that of the base wood. Laboratory tests typically show bondline shear strengths >10 MPa, ensuring structural reliability even under cyclical stress.

- Dimensional Stability: The lamination process mitigates the natural warping tendency of solid elm planks. Crosswise grain alternation can further enhance flatness retention, especially for wide tabletops.

- Surface Hardness and Wear Resistance: While elm is moderately hard, applying UV-cured polyurethane or aluminum oxide coatings can elevate surface durability to >3H pencil hardness, suitable for high-traffic furniture surfaces.

Aesthetic and Design Considerations

White Elm’s grain pattern is its defining aesthetic feature. When spliced correctly, the grain continuity across joints maintains visual harmony.

Designers can choose between:

- Random-matched splicing for a natural, rustic look.

- Book-matched splicing to mirror grain patterns, emphasizing symmetry.

- Slip-matched panels for a continuous flow of grain across wide surfaces.

Its color adaptability allows a broad palette of finishes — from light Scandinavian tones to deep walnut or espresso shades — without losing its textural character.

Common Technical Challenges

Despite its advantages, White Elm splicing boards present several technical considerations:

- Fiber Reversal: The interlocked grain can cause tear-out during planing; using a high-angle cutter head (≥40°) or carbide-tipped blades mitigates this issue.

- Adhesive Penetration: Elm’s porous texture demands controlled glue spread (typically 150–180 g/m²) to prevent starved joints or surface staining.

- Moisture Sensitivity: Elm is not naturally rot-resistant; applying UV-sealed polyurethane coatings or moisture barriers is essential for humid environments.

Quality control protocols — including bond-line inspection, surface scanning, and stress testing — are crucial to maintaining production consistency.

Sustainability and Resource Utilization

With increasing emphasis on sustainable forestry and waste reduction, the splicing process maximizes the utility of smaller White Elm logs and offcuts. Most suppliers now source timber from FSC-certified forests, ensuring traceability and responsible harvesting.

The lamination process also allows for engineered stability, reducing the need for large, old-growth lumber.

Applications and Emerging Trends

White Elm splicing boards are gaining popularity across sectors:

- Furniture manufacturing: Dining tables, desks, shelving, cabinetry.

- Architectural panels: Wall cladding, ceiling panels, acoustic boards.

- Custom joinery: Stair treads, handrails, and solid-edge countertops.

Recent innovations include cross-laminated elm composites and hybrid elm–metal structures, blending natural aesthetics with industrial durability.

The White Elm furniture splicing board embodies the balance between engineering precision and natural artistry. It offers designers and manufacturers a material that is technically sound, visually rich, and sustainably sourced. Understanding its structural behavior, adhesive technologies, and finishing dynamics is key to leveraging its full potential.