The North American White Elm splicing board has become one of the most sought-after engineered wood materials thanks to its excellent strength, dimensional stability, and natural aesthetic.

1. Product Functions & Core Uses

The North American White Elm splicing board serves as a premium engineered wood panel designed for structural, decorative, and high-end custom applications.

Built from carefully selected White Elm lumber that is spliced, laminated, and precision-finished, it provides:

Primary Functions

- Load-bearing capability for furniture frames, countertops, cabinetry, and interior structures.

- Surface stability for wide-panel applications such as tabletops, doors, and wall cladding.

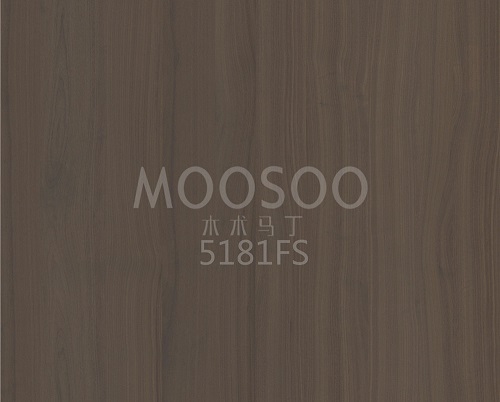

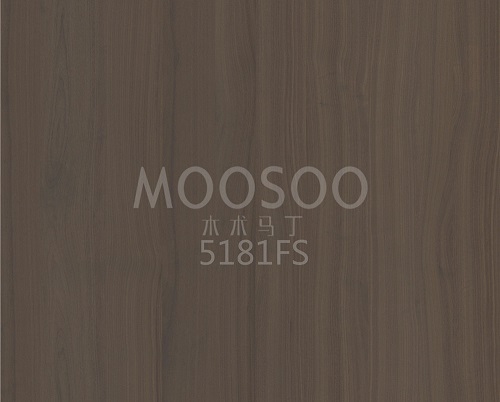

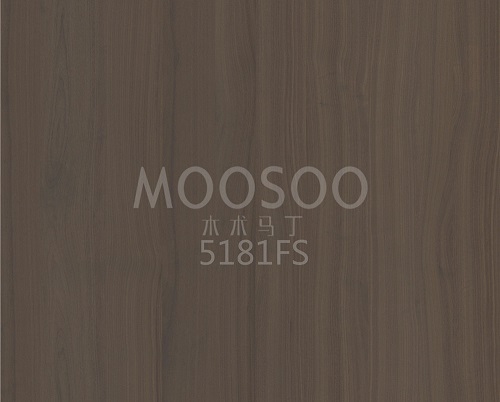

- Aesthetic enhancement through its elegant grain patterns, warm amber hues, and consistent texture.

- Improved machinability compared to natural solid wood, enabling efficient cutting, sanding, routing, and joinery.

Typical Use Scenarios

- Customized furniture manufacturing (dining tables, desks, shelving systems)

- High-end interior decoration (feature walls, stair treads, cabinet doors)

- Wooden crafts and boutique woodwork

- Architectural millwork and interior joinery projects

2. Product Features: Why White Elm Splicing Board Stands Out

Our North American White Elm splicing board is engineered to deliver high stability and exceptional aesthetic value.

Key highlights include:

- Superior Strength & Elasticity: White Elm wood is known for its interlocking grain, giving the board exceptional toughness and resistance to shear and splitting.

- Dimensional Stability: Through controlled kiln drying and finger-joint or laminated manufacturing, the board minimizes warping, shrinking, and expansion.

- High Machinability: The material responds smoothly to CNC operations, hand tools, and finishing techniques including staining, varnishing, and oiling.

- Eco-Friendly & Sustainable: We source our White Elm from responsible North American forests, following sustainable forestry guidelines.

- Rich and Distinctive Grain Texture: White Elm is recognized for its beautiful, wavy grain lines—making it ideal for luxury and visual-impact applications.

3. Technical Specifications of the White Elm Splicing Board

To meet diverse project requirements, our boards come in standard and customizable specifications:

Standard Specifications

- Material: North American White Elm (Ulmus Americana)

- Grades: A+, A, and B grade options available

- Moisture Content: 8–12% (kiln dried)

Construction Types:

- Edge-glued panels

- Finger-joint laminated panels

- Wide solid-laminated slabs

- Thickness Options: 12mm / 18mm / 25mm / 30mm / 40mm (custom sizes available)

- Width Options: 300mm–1200mm per sheet

- Length Options: 1.2m, 2.4m, 3m, or custom order

Optional Parameters

- Pre-sanded surface (120–240 grit)

- UV coating / matte clear finish

- FSC-certified supply chain

4. User Manual & Installation Guide

To help customers achieve optimal results, we provide a practical usage guide:

Before Use

- Store panels horizontally in a dry indoor environment.

- Allow boards to acclimate for 48–72 hours before installation.

- Inspect for grain direction to ensure visual consistency in assembly.

Processing Tips

- Use sharp carbide tools for cutting or routing.

- Sand progressively for best finish: 120 → 150 → 180 → 240 grit.

- Apply a sealing coat on all sides for moisture protection.

Installation Recommendations

- Leave a 2–4mm expansion gap for wall or cabinetry applications.

- Use high-strength wood glue for laminated assemblies.

- Finish with varnish, oil-wax, or polyurethane depending on project needs.

Maintenance Instructions

- Wipe with a dry or slightly damp cloth.

- Avoid prolonged water exposure.

- Re-oil or re-finish surface annually for best longevity.

5. Applicable Industries

The North American White Elm splicing board is widely adopted across multiple sectors due to its blend of visual appeal and performance:

- Furniture Manufacturing: Dining sets, bedroom furniture, office desks.

- Interior Architecture: Wall panelling, partition systems, staircases.

- Custom Joinery: Doors, frames, built-in cabinetry.

- Commercial Interiors: Restaurants, boutique stores, hotels.

- Luxury Woodcraft: Handcrafted décor, premium woodworking products.

6. Target Customers: Who Benefits the Most

Our product is tailored for professionals and businesses that demand stable, premium-grade engineered wood materials:

- Furniture factories and custom cabinetry workshops

- Interior designers and architectural design firms

- Woodworking studios and craft artisans

- Commercial builders and renovation contractors

- Importers, distributors, and bulk material suppliers

These customers value the consistency, durability, and upscale visual effect that White Elm provides.

The North American White Elm splicing board is a premium engineered wood solution that balances natural beauty with industrial-grade performance. From furniture manufacturing to architectural interiors, it supports both strength-critical and design-driven applications. With comprehensive specifications, rich grain texture, and professional usability, it stands as one of the most reliable materials for modern woodworking and high-end design.